Unconventional Hot Rubber

Hot retreading is a tyre rejuvenation process that involves vulcanizing the tyre at approximately 150°C within a mold. The tread and sidewall veneer of the tyre consist of non-vulcanized rubber compounds. The heating press is responsible for shaping and creating the tread design.

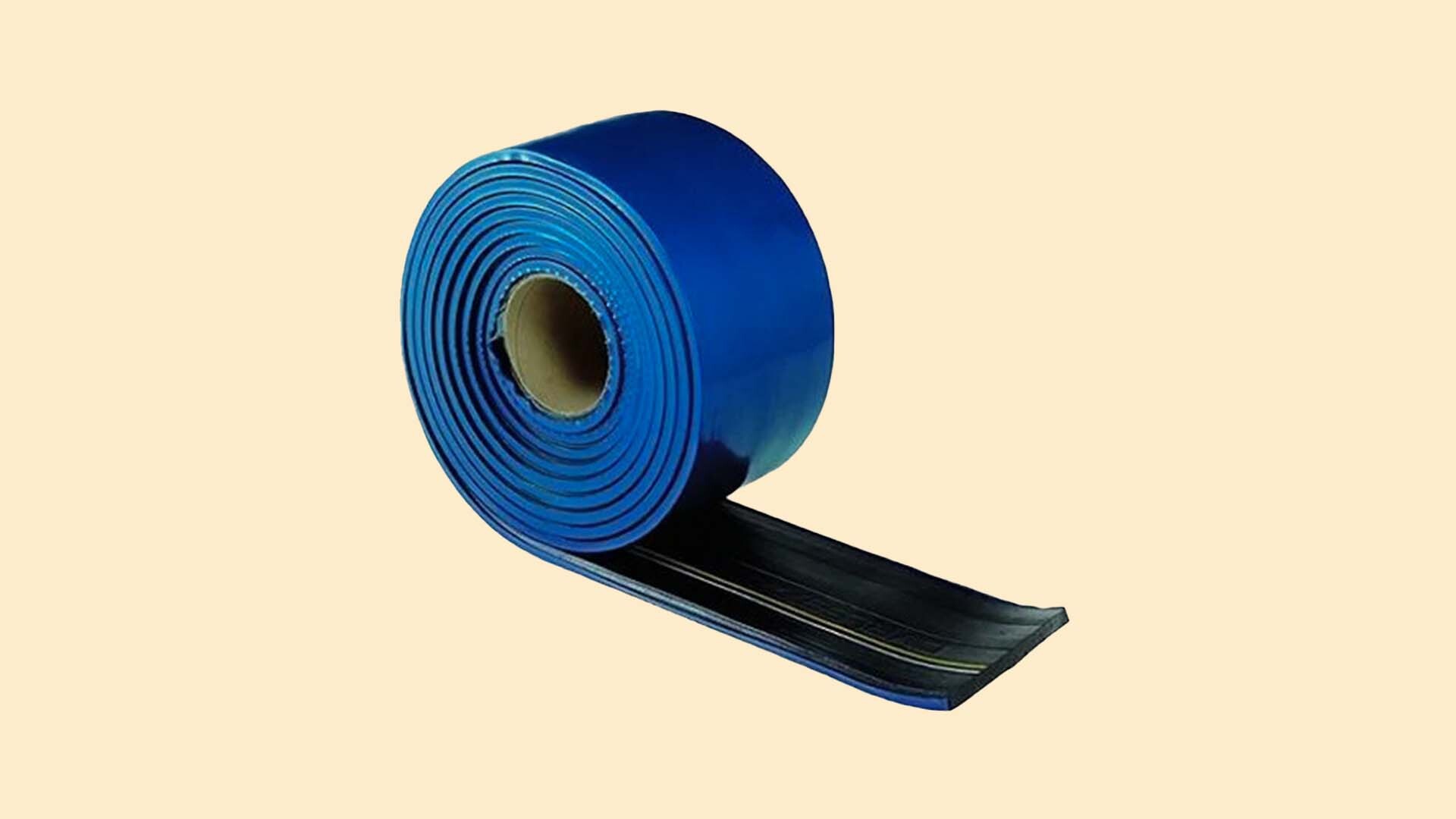

At our website, we offer Camel Back Tread, which features a thick layer of extruded rubber and cushion gum applied to the back surface. The uncured tread ensures low heat buildup, a moderate shelf life, and a quick curing time, resulting in significant energy savings. With precise sizing and exceptional interaction between the casing and the mold, our retreading solutions are ideal for Tractor Rear and OTR tyres.

While the conventional method of hot rubber retreading has been largely replaced by cold retreading in the global market, we continue to use hot rubber technology for manufacturing Tractor Rear and OTR tyre retreads.

The main advantages of hot retreading is that the side walls are renewed and the tyre remains regroovable.